Vehicle downtime when dealing with a fleet of commercial vehicles may be quite expensive for you or the business you work with. Businesses are frequently projected to lose between $450 and $750 a day, give or take, due to downtime. Therefore, all truck drivers and transportation businesses should make decreasing overall vehicle downtime a top goal which our truck driving school in Calgary aims at teaching.

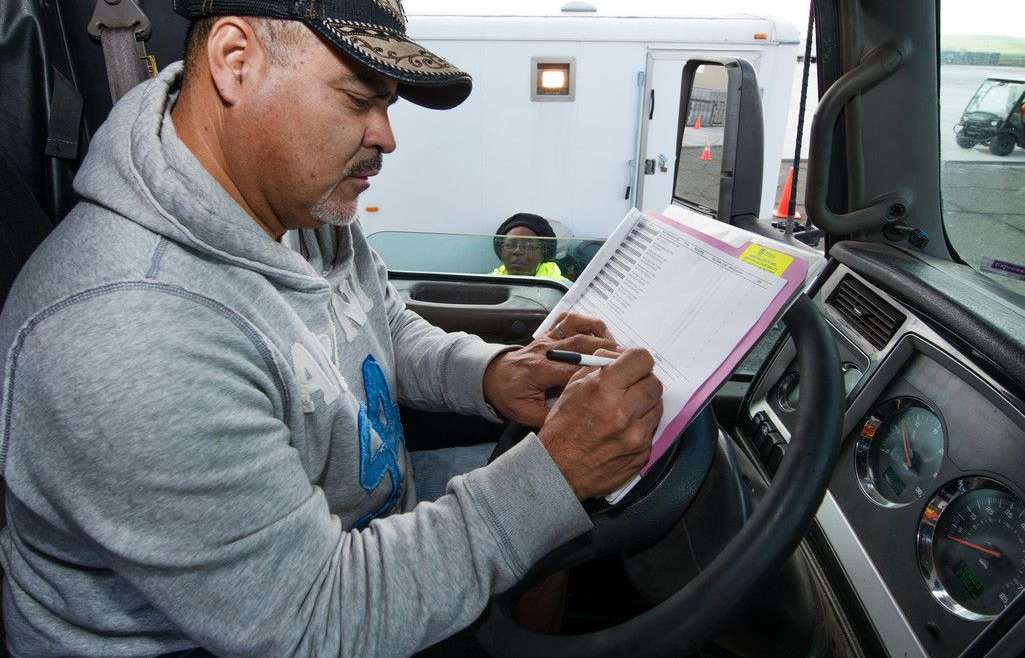

Implementing and using a quick and easy preventative truck maintenance checklist program is one method that truck drivers and businesses may reduce the amount of time that their vehicles are not in use.

You may save your fleet’s downtime by up to 20% and your total commercial vehicle maintenance/repair expenditures by using a reasonably straightforward semi-truck maintenance checklist. Additionally, it helps your car last longer so you don’t regularly need to invest in new vehicles and parts.

Continue reading to know what a truck maintenance checklist is like and what should be on it now that we have your attention.

An Overview of Commercial Truck Maintenance Checklists

A truck maintenance checklist, basically, is a paper or electronic document that lists review items that truckers, technicians, and any other relevant parties should or must check to make sure the provided commercial vehicle is in good working order and doesn’t require any emergency maintenance.

It is also crucial to keep in mind that commercial truck maintenance checklists might vary based on the specific vehicle and its intended use. In order to further prevent difficulties and breakdowns while driving, these truck maintenance checklists also assist drivers and fleet managers in staying on top of scheduling maintenance and repairs.

What Needs To Be On Your Truck Maintenance Checklist?

There are several fundamental factors to take into account when creating your own truck maintenance schedule and checklist. These factors will determine how successful your efforts to maintain your vehicle will be.

Preventative Maintenance Checklist

Above all, a solid and thorough preventative maintenance routine may assist you or the business you work for in maximizing the lifespan of the vehicle as opposed to being reactive and waiting until it is too late to solve an issue. Preventative maintenance attempts to foresee prospective problems before they arise and create a strategy to address the current problem before it worsens. Nevertheless, a preventative maintenance schedule should outline the suggested vehicle maintenance by the manufacturer as well as the estimated time each need should be finished.

Here are some common items you would want to include on your preventative commercial truck maintenance checklist, however, your semi-truck maintenance checklist will vary based on the kind of vehicle and its specifications.

- Does the oil require replacement?

- Should filters be replaced?

- Does anything need to be tightened?

- Does the engine require tuning?

- Do the brakes require adjusting or repairs?

- Is it necessary to rotate the tires?

- Is anything in need of lubrication?

- Does the radiator require maintenance?

Similarly, you can have a Demand Maintenance Checklist as well as a Crisis Maintenance Checklist that would be quite helpful for you to reduce the downtime of your truck.

For more information like this, enroll on simple yet super-effective truck driving courses at our leading truck driving school in Calgary.